High temperatures can cause serious damage to equipment and structures. Whether in factories, oilfields, or industrial plants, extreme heat needs to be controlled. This is where high temperature insulation comes in. It helps protect materials, improves efficiency, and keeps workers safe. In this blog, we will explain what high temperature insulation is, why it is important, and how it works.

What Is High Temperature Insulation?

High temperature insulation is a special material that reduces heat transfer. It is used in places where extreme heat is present, such as industrial plants, pipelines, and oilfield buildings. This insulation helps keep equipment from overheating and reduces energy loss.

Different types of high temperature insulation include:

- Ceramic fiber insulation – Used in furnaces and kilns because it can handle high heat.

- Calcium silicate insulation – Found in pipes and boilers to prevent heat loss.

- Mineral wool insulation – Used in construction and industrial applications.

These materials are lightweight, durable, and able to handle temperatures over 1,000°F (538°C).

Benefits of High Temperature Insulation

Energy Efficiency

One of the biggest benefits of high temperature insulation is energy savings. Without insulation, heat escapes from equipment and pipes. This means more energy is needed to keep systems running. Proper insulation reduces energy loss and lowers costs. According to the U.S. Department of Energy, industrial insulation can cut energy use by 20-30%.

Protects Equipment and Structures

Heat can cause serious damage to machines, pipes, and buildings. Over time, high temperatures can weaken metal and other materials. Insulation helps control heat, preventing damage and extending the life of equipment.

Worker Safety

Hot surfaces can be dangerous. Workers can get burns if they touch unprotected pipes or machines. High temperature insulation helps reduce surface temperatures, making the work environment safer. According to OSHA, thermal insulation can lower burn risks in industrial settings.

Environmental Benefits

Using less energy means reducing carbon emissions. High temperature insulation helps industries lower their environmental impact by cutting down on fuel use. This is good for the planet and can also help companies meet environmental regulations.

How High Temperature Insulation Works

High temperature insulation works by slowing down heat transfer. It does this through conduction, convection, and radiation control.

- Conduction: Heat moves through solid materials. Insulation slows this down by trapping air pockets.

- Convection: Heat moves through liquids and gases. Insulation blocks this by preventing airflow.

- Radiation: Heat moves in waves. Special insulation materials reflect these waves to reduce heat loss.

By combining these methods, insulation keeps heat where it is needed and prevents it from escaping.

Where Is High Temperature Insulation Used?

High temperature insulation is used in many industries, including:

- Oil and gas – Protects pipelines, oilfield buildings, and storage tanks.

- Power plants – Helps manage heat in boilers and steam pipes.

- Manufacturing – Used in furnaces, kilns, and ovens.

- Construction – Keeps buildings safe from fire and extreme heat.

Choosing the Right High Temperature Insulation

Selecting the best insulation depends on the application. Factors to consider include:

- Temperature range – Choose materials that can handle the specific heat level.

- Durability – Ensure the insulation can withstand harsh conditions.

- Installation process – Some insulation is easier to apply than others.

- Cost-effectiveness – Balance initial cost with long-term savings.

Experts in the field can help determine the right insulation for each situation.

Conclusion

High temperature insulation is essential for safety, efficiency, and environmental protection. It saves energy, protects equipment, and keeps workers safe. Industries that use high temperature insulation benefit from lower costs and improved performance.

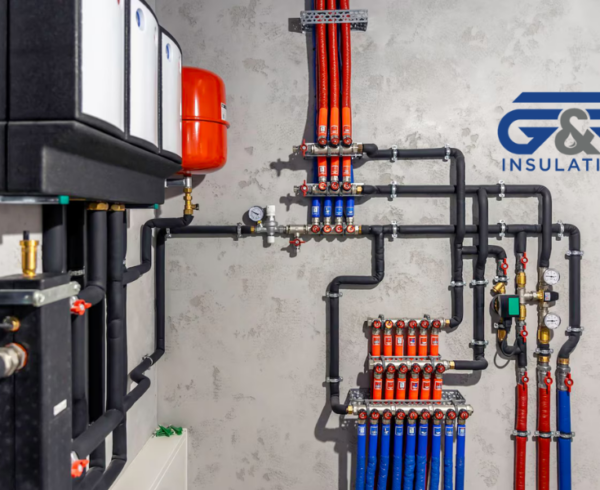

Providing quality service and products is key to ensuring effective insulation solutions. Trained professionals play an important role in managing insulation jobs safely and efficiently. G&R Insulating specializes in mechanical piping insulation, oilfield buildings, glycol tubing installation, utilidors, vessel and tank insulation, insulated blankets, and scaffolding services.

If you need high temperature insulation solutions, contact an expert today to learn more about the best options for your needs!