Industrial tanks are used to store many types of materials. These materials can include water, oil, chemicals, and more. Keeping the right temperature inside these tanks is very important. This is where tank insulation helps.

Insulation works like a blanket. It keeps the heat in or out, depending on what you need. Tank insulation helps protect the contents of the tank, saves energy, and makes the site safer.

Let’s take a closer look at what tank insulation is, why it matters, and how it can help in many industries.

Why Do We Need Tank Insulation?

Tank insulation has many important jobs. It is used in factories, oil fields, power plants, and other places. Here’s why it matters:

Keeps Temperatures Stable

Tanks often store hot or cold materials. Without insulation, heat can escape or get in. This can change the temperature inside the tank. That’s a problem for materials that need to stay at a certain temperature.

For example, in the oil and gas industry, tanks often hold heated materials. If they cool down, it costs money to heat them again. Insulation keeps that heat from escaping.

Saves Energy and Money

Insulated tanks use less energy. This is because they don’t need as much heating or cooling. Less energy means lower power bills and smaller carbon footprints.

Improves Safety

Some tanks hold very hot or very cold materials. Without insulation, the outside of the tank can be dangerous. Workers can get burned or hurt by touching them.

Insulation acts like a shield. It keeps the tank surface safer for workers. It also helps prevent leaks or damage caused by changes in temperature.

Protects the Environment

Tanks without insulation can lose heat or cool air. That wasted energy affects the environment. Also, temperature swings can cause leaks, spills, or emissions.

Insulated tanks are better sealed. They lower the risk of pollution. This helps companies follow safety and environmental rules.

What Materials Are Used for Tank Insulation?

Many materials are used to insulate tanks. The best type depends on what the tank holds, and where it is.

Fiberglass

Fiberglass is one of the most common insulation types. It’s light, easy to install, and works well in hot or cold weather. It’s also not too expensive.

Mineral Wool

Mineral wool is made from rock or slag. It can handle very high temperatures. It is also good at blocking sound and doesn’t burn easily.

Foam Insulation

Foam insulation, like polyurethane foam, sticks right to the tank. It creates a tight seal. This makes it great for tanks that must stay very cold or hot.

Insulated Blankets

Some tanks use removable blankets. These are useful for tanks that need repairs or checks. You can take them off and put them back easily.

Where Is Tank Insulation Used?

Tank insulation is used in many places. It helps many industries work better and safer. Some common areas include:

Oil and Gas Fields

Oil tanks must keep fuel at a certain temperature. Insulation keeps oil from freezing or thickening. This helps keep pumps and pipes running.

Chemical Storage

Chemicals often need special conditions. Too much heat or cold can change their makeup. Insulation helps keep them stable and safe.

Water and Waste Treatment

Tanks in water plants often face freezing winters. Insulation keeps water flowing and stops pipes from freezing.

Choosing the Right Tank Insulation

Not all tanks are the same. Choosing the right insulation depends on:

- Tank size

- What’s inside the tank

- Location (hot or cold climate)

- Safety rules and standards

It’s important to work with trained experts. They will know what type of insulation fits best.

How Is Tank Insulation Installed?

Tank insulation is not a one-size-fits-all job. Here’s how the process works:

Clean the Tank Surface

Before adding insulation, workers clean the tank’s outside. This helps the insulation stick well.

Add the Insulation Material

Workers wrap the tank with the chosen insulation. They might spray foam, wrap fiberglass, or use blankets.

Seal and Cover It

A metal or plastic sheet often covers the insulation. This protects it from rain, wind, or damage.

Check for Safety

Experts test the insulation after it’s installed. They check for leaks, air gaps, or unsafe spots.

Benefits of Using a Trusted Service

Getting tank insulation from trained professionals is key. They know how to do the job right. Their team follows all safety steps to ensure safe and proper installation.

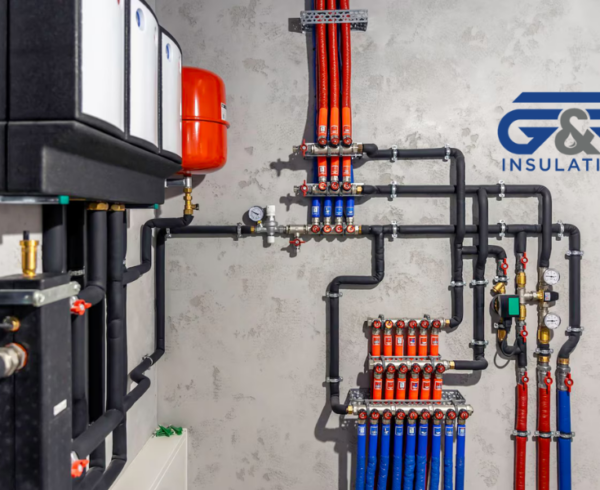

Companies like G&R Insulating are known for quality work. They offer many services, including:

- Mechanical piping insulation

- Oilfield building insulation

- Glycol tubing installation

- Utilidors

- Vessel and tank insulation

- Insulated blankets

- Scaffolding services

They train their staff and prepare them for every job. Their goal is to help projects run safely and on time.

Conclusion: Why Industrial Tank Insulation Matters

Industrial tank insulation is more than just wrapping a tank. It helps keep materials safe, saves energy, and protects workers and the planet. Whether it’s for oil, chemicals, food, or water, insulation is key to keeping things running well. Choosing trained experts ensures the insulation lasts and works as it should. Quality service means fewer problems and better results.

G&R Insulating is one of the trusted names in the field. They make sure their team is ready to handle each job with care and safety. From tanks to pipes and buildings, their work helps companies stay safe, efficient, and ready for anything.