When we talk about industrial pipe insulation in Grande Prairie, Alberta, it’s important to know how helpful it is for businesses. Insulating pipes the right way saves energy, stops damage, and makes places safer in industries like oilfields and factories. In this blog, we will explain what industrial pipe insulation is, why it’s needed, and how it can help your business.

Let’s dive into the key points that will help you understand this essential service.

What is Industrial Pipe Insulation?

Industrial pipe insulation is the process of wrapping or coating pipes with materials designed to reduce heat loss or prevent freezing. Temperature changes can affect pipes that carry hot or cold fluids, causing energy loss or even damage. Insulating pipes helps control these temperature fluctuations.

You can use several materials for pipe insulation, including fiberglass, foam, and rubber. You choose the insulation material based on the temperature of the fluid in the pipes and the environment where you install the pipes.

Why is Pipe Insulation Important?

- Energy Efficiency: One of the main reasons for insulating pipes is to improve energy efficiency. When pipes are not insulated, they lose heat or cool air, making heating and cooling systems work harder. Insulating your pipes helps to maintain the desired temperature, which reduces energy consumption and lowers your utility bills.

- Prevent Freezing: In colder climates like Grande Prairie, Alberta, pipes are at risk of freezing in the winter months. Frozen pipes can burst, causing costly damage and unsafe conditions. Insulating pipes helps keep them from freezing by maintaining the temperature inside the pipes. This is particularly important for pipes that carry water, steam, or chemicals.

- Safety and Protection: Insulating industrial pipes also offers safety benefits. Hot pipes can cause burns or other injuries, especially in workplaces where workers are around them regularly. Proper insulation reduces the risk of contact with hot surfaces, keeping employees safe. It also helps prevent condensation from forming on cold pipes, which can create slippery areas and lead to accidents.

- Extended Pipe Life: Over time, pipes that are exposed to extreme temperature changes can become damaged or worn. Insulating your pipes protects them from the elements, reducing wear and tear and helping to extend the lifespan of your pipes. This can save your business money in the long run by preventing costly repairs and replacements.

Choosing the Right Pipe Insulation Material

When choosing insulation for your pipes, it’s important to consider the specific needs of your facility. Here are some popular types of insulation materials:

- Fiberglass Insulation: Fiberglass is one of the most common insulation materials. It’s effective at both heat retention and preventing heat loss, making it ideal for pipes that carry hot or cold liquids. Fiberglass is also resistant to mold and mildew, making it a great choice for areas with high moisture.

- Foam Insulation: Foam insulation is a popular choice, especially for pipes that need extra temperature protection. It is light, stretchy, and easy to put in. Foam works well in homes and businesses, keeping pipes safe from temperature changes.

- Mineral wool: is a strong material used for insulation in factories. It can resist fire and works well in hot places, like steam pipes. It also helps reduce noise, which is useful in some areas.

- Rubber insulation: is flexible and is used for pipes that need to stop shaking or noise. It handles both hot and cold temperatures and resists getting wet, making it great for outdoor use.

Installation Process of Industrial Pipe Insulation

Installing industrial pipe insulation requires a skilled team to ensure it’s done properly. Here’s a general overview of the process:

- Assessing the Pipes: The first step is to evaluate the pipes that need insulation. This includes checking the type of pipes, their location, and the temperature of the fluids they carry.

- Choosing the Insulation Material: Based on the pipe assessment, the right insulation material is chosen. The material needs to be appropriate for the temperature, pipe size, and environment.

- Measuring and Cutting: After selecting the material, it needs to be measured and cut to fit the pipes precisely. This ensures that there are no gaps where heat can escape.

- Installing the Insulation: The insulation is then applied around the pipes. We secure it tightly to prevent movement and seal the edges to ensure maximum efficiency. For outdoor pipes, we may apply additional weather-resistant coatings.

- Testing and Maintenance: After installation, it’s important to test the pipes to ensure that the insulation is effective. Regular maintenance should be performed to check for any damage or wear over time.

How Can Pipe Insulation Benefit Your Business?

- Cost Savings: By reducing energy loss, you can lower your energy bills, which can add up to significant savings. Insulating pipes is an investment that pays off over time by reducing the need for energy-hungry systems to maintain the desired temperatures.

- Improved Safety: Ensuring that pipes are insulated reduces the chances of workplace injuries. It creates a safer environment for your employees and anyone else around the facility.

- Environmental Impact: When you reduce energy consumption by insulating pipes, you’re also contributing to environmental conservation. Less energy use means fewer greenhouse gas emissions and a smaller carbon footprint.

Conclusion

Industrial pipe insulation in Grande Prairie, Alberta, helps save energy, stop pipes from breaking, keep people safe, and make pipes last longer. By choosing the right insulation and installing it properly, your business can save money and get benefits for a long time.

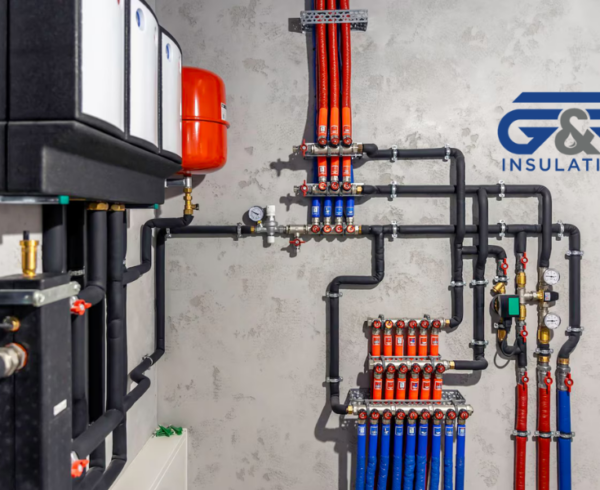

At G&R Insulating, we understand the importance of quality service and products. We train our team to manage insulation jobs safely and efficiently, ensuring the best results for you. We offer a wide range of services, including mechanical piping insulation, oilfield building insulation, glycol tubing installation, and much more.

Contact us today to learn more about how we can help improve your business’s energy efficiency and safety with top-notch industrial pipe insulation services.