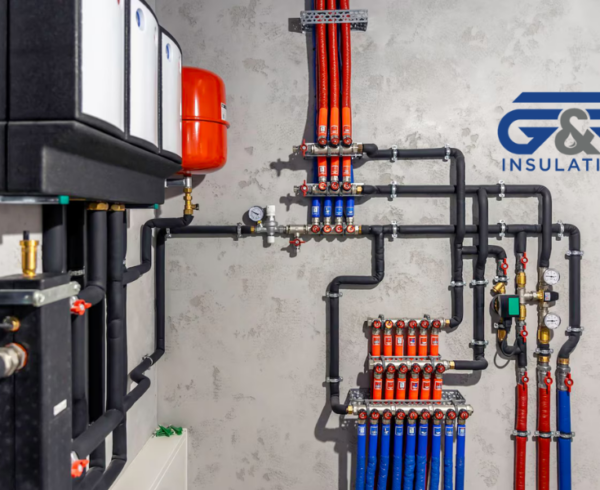

Heating and cooling help most buildings provide comfortable indoor environments and they rely on mechanical systems in doing so. However, HVAC systems often overlook a very essential part of them – pipe insulation. As it was stated before but bears repeating once more mechanical pipe insulation plays a key role in increasing energy efficiency by reducing heat loss or gain through pipes. This simple yet very effective way makes sure that there is no change of temperature inside the pipes hence lower electricity bills as well as faster operations of other appliances in the house/community.

Basics of Mechanical Pipe Insulation

Types of Pipe Insulation Materials

Before plunging into the importance of mechanical pipe insulation for strength efficiency, it is important to understand the exclusive forms of substances used for insulating pipes. Various substances together with fiberglass, foam rubber, polyethylene, and mineral wool are normally used for this cause. Deciphering the most ideal choice for your specific needs requires understanding the attributes and merits of every individual constituent.

| Fiberglass | Durable and cost-effective |

| Foam Rubber | Flexible and easy to install |

| Polyethylene | Moisture resistant |

| Mineral Wool | Excellent thermal performance |

Installation Methods

Proper installation is very key to effective heat loss reduction and energy savings through proper insulation. Understanding the many setting-up methods (pre-shaped insulation, insulation blankets, spray foam, etc.) will help you settle on an application that is right for your tubes.It is vital to comply with manufacturer pointers and great practices to attain the most advantageous effects.

Thermal Performance Benefits

Reduced Heat Loss or Gain

With effective mechanical pipe insulation, there is a significant reduction in heat loss or gain through the piping system. Little to no thermal energy is wasted, ensuring that the transported fluids maintain their desired temperature levels efficiently.

Operational Cost Savings

There are also operational expense savings with mechanical pipe insulation. It helps to reduce the amount of heat lost or gained thereby diminishing energy consumption and costs that are related to maintaining ideal temperatures in different industry processes. It has been established that energy costs could be cut by about 20% through well-insulated pipes.

Additional Advantages of Pipe Insulation

Moisture Control and Corrosion Prevention

There is one method of protecting pipes from corrosion and prolonging their service time by ensuring proper humidity content control. Mechanical insulation maintains thermal insulation and averts moisture penetration from reaching them as applied to pipes. That is because when pipes are insulated against heat loss, water vapor in warm air condenses on the inside wall surface and mixes with oxygen-dissolved in rainwater or other liquids flowing through them thereby resulting in oxidation.

Noise Reduction and Safety Enhancement

In addition to the fact that pipe insulation helps in reducing noise while at the same time improving safety. This is achieved through vibration damping where insulated pipes are used therefore minimizing noise in residential and commercial structures. Also, in heat hot water pipes, for instance, the uniform temperatures through insulations help in reducing chances of getting burnt and general safety in building premises. Therefore, one should not worry about his or her water getting cold and has to be boiled again. Insulation of pipes is aimed primarily at preventing heat losses as well as ensuring that energy is used efficiently.

Considerations and Best Practices

Selecting the Right Insulation for Your Pipes

To guarantee optimum energy efficiency and performance, the selection of the most appropriate insulation for your pipes is very important. Temperature range, material compatibility, and moisture resistance should be borne in mind amongst other factors. Insulation materials with high R-values should be chosen to give the maximum thermal resistance and minimize heat loss. The general performance of their system can be greatly affected by the insulation which they will decide to use

Maintenance and Longevity of Insulation Materials

The efficiency of the mechanical pipe insulation can be sustained by frequent inspection and maintenance of the insulation materials. The insulation’s longevity depends on its proper installation which includes sealing joints and ensuring a snug fit to reduce heat loss. Regular maintenance checks will enable you to identify such wear signs earlier thereby enabling timely replacements and repairs to be made. These materials “may last for…the duration of an average person’s life or more”

Conclusion

Mechanical pipe insulation is indispensable in enhancing the energy efficiency of many industrial and commercial facilities at present. Its main work is to prevent heat loss or lessening on the pipes which enables fluid temperature control hence reducing the consumption of energy hence lower costs incurred. It can also prevent condensation accumulation which causes rust and pipe destruction. As a whole, such a type of insulation constitutes some of the basic elements required.

Frequently Asked Question

Q: How Does mechanical pipe insulation improve energy efficiency?

A: The use of mechanical pipe insulation can minimize heat losses or stop condensation from arising on streams and hot liquid pipes since less power will be employed in cases when water has the desired heat.

Q: What materials are commonly used for mechanical pipe insulation?

A: Common materials used for mechanical pipe insulation are fiberglass, mineral wool, foam insulation, and rubber insulation among others depending on temperature range, moisture resistance, and durability factors.

Q: How does mechanical pipe insulation help prevent freezing pipes?

A: Insulating pipes helps to maintain a consistent temperature, preventing pipes from freezing in cold weather. By retaining heat in hot water pipes and providing a barrier of insulation for cold water pipes, the risk of freezing and bursting is significantly reduced.

Q: Does mechanical pipe insulation help reduce noise from pipes?

A: Yes, mechanical pipe insulation can indeed help in reducing noise from pipes by absorbing and dampening vibrations caused by water flow. This can be more useful, especially in buildings where there are noisy pipes that may interrupt occupants.